The surface of the board can be easily decorated

with most varieties of paints, wall papers,

laminates, veneers and ceramic tiles. These

boards are compatible with common building

materials and galvanized steel.

The surface of the board can be easily decorated

with most varieties of paints, wall papers,

laminates, veneers and ceramic tiles. These

boards are compatible with common building

materials and galvanized steel.

| DIMENSIONS | THICKNESS | WEIGHT | EDGE PROFILE |

|---|---|---|---|

| 2440mm X 1220mm | 18mm | 26.24 Kg/m2 | Square |

| 2440mm X 1220mm | 16mm | 23.32 Kg/m2 | Square |

Note: Special sizes are also available on request

Hicem Boards are cured in HPSC [High Pressure Steam Curing]

which cause an irreversible chemical change, thus providing high dimensional

and chemical stability accompanied by low alkalinity.

| PARAMETER | UNIT | STANDARD | TYPICAL VALUE |

|---|---|---|---|

| Alkalinity | pH | --- | 8~9 |

| DIMENSIONS | THICKNESS | STANDARD | METHOD OF LOADING ON SPECIMEN | DEFLECTION | LOAD AT FAILURE |

|---|---|---|---|---|---|

| 600mm (W) x 600mm (L) |

18mm | AS/NZS 1170.1:2002 |

Load at failure of 18mm thickness board using a iron ball of 63mm diameter |

9.8mm | 3108 N |

| 600mm (W) x 600mm (L) |

18mm | AS/NZS 1170.1:2002 |

Load is applied through an area on 18mm thick board |

20mm | 4665 N |

Note: When the load is applied through an area, the withstanding capacity of board of size 600 x 600 x 18 mm is 0.53 N/mm2

| PARAMETERS | UNIT | STANDARD | TYPICAL VALUE |

|---|---|---|---|

| Apparent Density (EMC) |

Kg/m3 | IS 14862:2000 | >1200 |

| Modulus of Rupture (EMC) |

MPa | IS 14862:2000 | Parallel -14 / Perpendicular - 8 |

| Impact Strength | J/m2 | --- | >2100 |

| Compressive Strength | MPa | ASTM D1037 | > 30 |

| Tensile Strength | MPa | ASTM D1037 | Parallel – 20 Perpendicular - 18 |

| Screw Withdrawal Strength |

N | IS 2380 Part XIV | >1300 |

| Moisture Content (EMC) |

% | --- | <12 |

| PARAMETERS | RESULTS |

|---|---|

| Water Impermeability | Passes |

| Frost Resistance (Freeze/ Thaw Tests) | Passes (for 100 cycles of test) |

| Warm Water | Passes (for 56 days) |

| Soak Dry | Passes (for 50 cycles of test) |

| Heat Rain | Passes (for 50 cycles of test) |

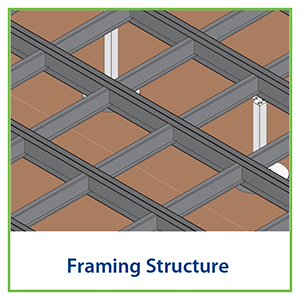

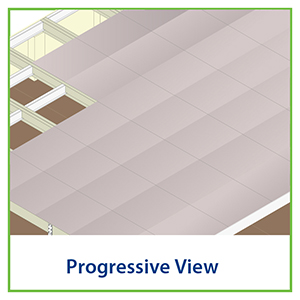

M.S frame structure design to be done by the Structural Engineer.

Grid should not exceed 600mm x 600mm or 900mm x 600mm .

| PARAMETERS | RESULTS |

|---|---|

| Combustibility | Non-Combustible, BS476 Part IV Séries |

| Surface Spread of Flame | Class 1 as per BS 476:Part 7 |

| Flame Spread index | 0' as per ASTM E 84;16 |

| Fire Propagation Test | I= 0.7 as per BS 476 : Part 6 |

| Ignitability | Class P is not easily ignited as per BS 476:Part 5 |

| Smoke Developed Index | 18 as per ASTM E84:16 |

| PARAMETERS | RESULTS |

|---|---|

| Moisture Content at EMC | <12% |

| Water Absorption | ~38% |

| Change in Thickness due to Swelling in Water (mm) |

0.003 |

| Shrinkage Dimensional | 0.19 % |

| Difference in Thickness (mm) | 0.04 |